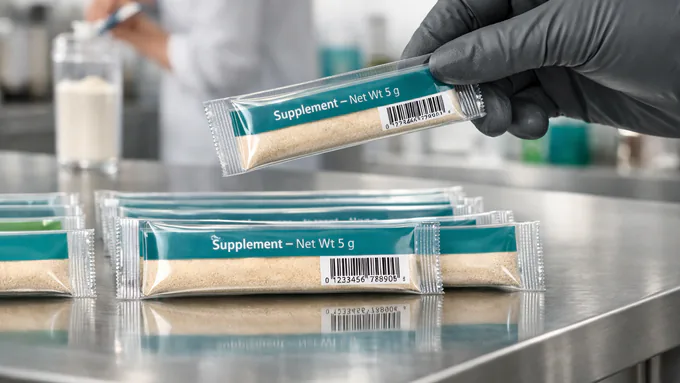

Custom Stick Pack Manufacturing

Deliver convenience and portion control with single-serve stick packs engineered for barrier, fill accuracy, and retail-ready presentation—produced in FDA- and cGMP-certified facilities.

Stick Packs Built for Speed and Shelf Life

We match films and seals to your product’s sensitivity, validate fill weights, and design cartons for throughput and compliance.

Barrier by Design

Foils and laminates tuned for moisture, oxygen, and light protection to preserve potency and shelf life.

Throughput First

High-speed multi-lane fillers with seal windows validated to reduce rejects and improve run rates.

Channel-Ready

Artwork, coding, and cartons aligned to FDA and retailer standards for faster onboarding and compliance.

Formats

- 2–15g fills

- Straight or shaped cuts

- Easy-tear notches

- Matte, gloss, or metallic films

Applications

- Hydration powders

- Electrolytes & energy blends

- Collagen & proteins

- Greens & botanicals

Quality & Compliance

- Fill weight checks

- Seal integrity testing

- Lot & expiry coding

- Full traceability

Cartons & Kitting

- Retail cartons & sleeves

- Bundles & multipacks

- Sampling formats

- 3PL integration

Our Stick Pack Workflow

A five-stage path to accurate fills, tight seals, and compliant packaging.

Brief & Targets

Claims, audience, budget, fill size, and carton plan aligned to manufacturable specs.

Film & Tooling

Barrier films and sealing jaws defined for speed, protection, and ease of use.

Prototype & Seal Window

Short runs validate fill weights, tear performance, and seal strength across lanes.

Pilot Verification

Line trial confirms yield, coding, seal integrity, and carton fit with distribution tests.

Release

Final specs, artwork, COAs, and production documentation prepared for repeatable scale.

Quality, Documented

Every lot is traceable from film rolls to finished cartons, with in-process testing aligned to your label, claims, and channel standards.

- Fill weight variation & uniformity

- Seal strength & tear tests

- Lot/expiry coding verification

- Retail carton integrity

Stick Pack Specialties

Differentiate with format, finish, and barrier—optimized for throughput and compliance.

Portion & Convenience

- Single-serve 2–15g packs

- On-the-go consumer usability

- Easy-tear notches & opens

- Travel & sampling formats

Performance & Stability

- Moisture & oxygen barrier films

- Foil & laminate protection

- Accelerated stability guidance

- Seal strength validation

Brand Presentation

- Custom printed foils

- Gloss, matte, metallic finishes

- Retail cartons & sleeves

- Marketplace-ready compliance

Stick Pack FAQs

Details on fill weights, films, cartons, and lead times.

What fill sizes do you support?

Typical stick packs range from 2–15g depending on density. We’ll align film width and lane configuration to your target dose.

What types of films are available?

Common structures include PET/foil/PE, metallized PET, and high-barrier laminates. We match based on moisture/oxygen needs and branding goals.

Can you provide retail cartons and multipacks?

Yes. Stick packs can be cartoned in 10-, 14-, 15-, 20-, or 30-count sleeves, with options for retail cartons, bundles, and ship-ready packs.

What are typical lead times and MOQs?

Lead times depend on film sourcing, printing, and carton production. We support flexible MOQs and propose the fastest compliant path to launch.