Custom Powder & Drink Mix Manufacturing

High-performance powders engineered for solubility, mouthfeel, and stability—built to run at scale in FDA- and cGMP-certified facilities.

Powders That Disperse, Taste Great, and Scale

We tune particle size, density, and flavor systems so your blend pours cleanly, dissolves fast, and holds spec from pilot to production.

Flow & Density Engineering

Bulk/tapped density targeting, anti-cake strategy, and flow aids dialed in to reduce dusting, segregation, and fill-weight drift in high-speed packaging.

Solubility & Mouthfeel

Granulation or instantization (by facility), sweetener/acid balance, and de-foaming guidance for clean dispersion, clarity, and consistent sip experience.

Channel-Ready Documentation

COAs, master labels, and pack specs aligned to FDA and retailer/marketplace standards to keep onboarding fast and listings live.

Blend Architecture

- Actives & carriers selection

- Particle size & mesh targeting

- Anti-cake & flow aids strategy

- Flavor, sweetener, acid systems

Sensory & Experience

- Solubility & dispersion testing

- Mouthfeel & grit reduction

- Foam control & clarity

- Aroma & color alignment

Quality & Stability

- Moisture (LOD) & water activity

- Micro & heavy metal compliance

- Accelerated stability guidance

- Oxidation & hygroscopicity controls

Pack Formats

- Stick packs & sachets (single-serve)

- Gusseted pouches & bags

- Jars & tubs with scoops

- Nitrogen flush & desiccants (by facility)

Our Powder Workflow

A five-stage path to fast-dissolving blends, tight yields, and clean audits.

Brief & Targets

Claims, flavor direction, serving size, and pack format aligned to a manufacturable plan with target density and costed BOM.

Architecture

Actives, carriers, anti-caking, and sweetener/acid systems set; risks for hygroscopic actives and oxidation addressed early.

Prototype

Bench blends with accept criteria for density, dispersion time, foam, mouthfeel, and flavor; fill-weight targets modeled by pack format.

Pilot & Verification

Pilot run confirms blend uniformity, dust control, and packaging throughput; label logic and COAs validated.

Release

Final spec, master label, and documentation package for repeatable scale and fast channel onboarding.

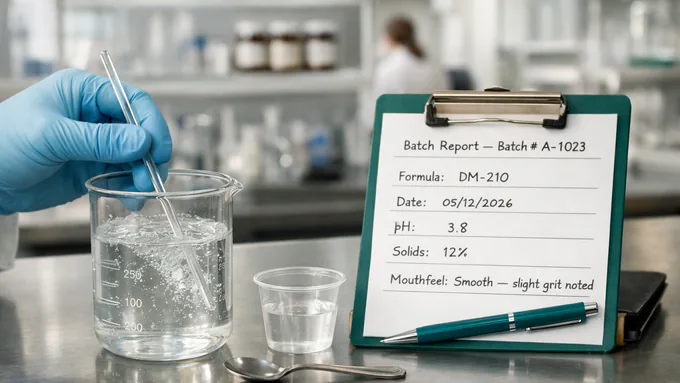

Quality, Documented

Every prototype and lot is traceable—tight paperwork keeps scale-up predictable and audits straightforward.

- Blend uniformity & sieve analysis

- Bulk/tapped density & flow testing

- Moisture (LOD) & water activity (aw)

- Potency, micro, heavy metals

- In-process net weight & seal integrity

- Change control & versioned formulas

Powder Specialties & Formats

Choose the experience and pack format that fit your brand—then let our team engineer it to scale.

Functional Blends

- Protein, collagen, & meal support

- Greens, reds, & adaptogens

- Pre-, intra-, & post-workout

- Nootropics & metabolic support

Sensory & Stability

- Natural & artificial flavors

- Stevia, monk fruit, sucralose, blends

- Citric/malic acid balance & Brix

- Anti-oxidation & moisture control

Packaging & Presentation

- Stick packs (1–15 g typical)

- Sachets/sample packs

- Gusseted pouches & tubs with scoops

- Retail cartons, kitting, & displays

Powder FAQs

Answers on solubility, packaging, timelines, and MOQs.

Can you help with clumping and moisture issues?

Yes. We address hygroscopic actives with carrier selection, anti-caking strategy, barrier films, and desiccants or nitrogen flush where supported.

Do you make stick packs and sachets?

We run single-serve stick packs and sachets, plus pouches and tubs. Scoop sizing and net-weight targets are engineered into the plan.

How do you improve solubility and mouthfeel?

We tune particle size, density, and sweetener/acid balance; employ de-foaming guidance and, where appropriate, instantization or granulation options.

What are typical lead times and MOQs?

Lead times vary by ingredients and packaging. We support flexible MOQs and prioritize the fastest compliant path to launch.