Research and Development

APEX CSM turns product ideas into shelf-ready supplements with disciplined formulation, sensory optimization, and stability planning—so you launch faster with labels you can stand behind.

From Idea to Validated Formula

We bridge marketing intent and manufacturability—balancing claims, cost, sensory, and scalability—so your first pilot behaves like your production run.

Speed Without Guesswork

Tight, phased R&D sprints with clear accept/reject criteria compress timelines while protecting label accuracy and stability goals.

Formulation That Scales

Excipients, flow, and density tuned early for capsules, tablets, powders, gummies, liquids, softgels, and specialty formats.

Retail & Marketplace Ready

Documentation and label logic aligned to FDA and channel standards to keep onboarding friction low and listings live.

Core R&D

- Concept & claims mapping

- Ingredient & vendor strategy

- Dosage form selection

- Prototype & pilot runs

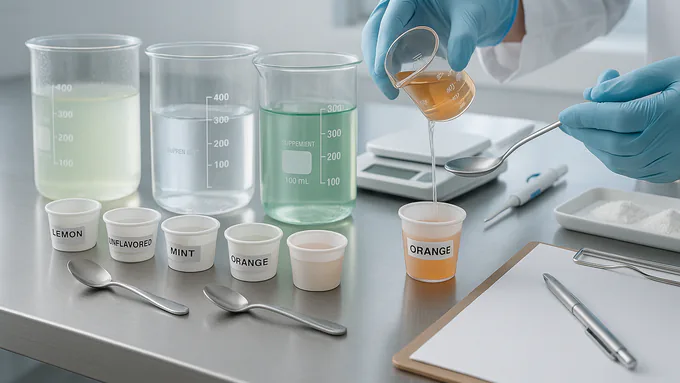

Sensory & Experience

- Flavor systems & maskers

- Sweeteners & acids balance

- Mouthfeel & solubility

- Color & visual appeal

Quality & Stability

- Identity, potency, purity to spec

- Micro & heavy metal screening

- Accelerated stability guidance

- Shelf-life rationale & packaging fit

Compliance Support

- Supplement Facts logic

- Structure/function claims

- Allergen & warning language

- Retailer & Amazon readiness

Our R&D Process

A five-stage path that preserves speed while tightening documentation at each milestone.

Brief & Targets

Outcomes, audience, claims, budget, and timelines aligned to a realistic dosage form and costed plan.

Architecture

Active selection, excipient strategy, and flavor direction set; risks and stability levers identified early.

Prototype

Lab batches with accept criteria for potency, flow/press, solubility, mouthfeel, and sensory notes.

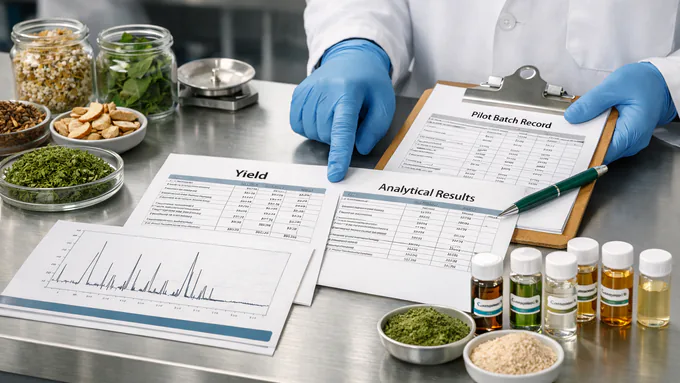

Pilot & Verification

Pilot run to confirm throughput and yields; label logic, COAs, and packaging fit validated.

Release

Finalized spec, master label, and documentation package for manufacturing and channel onboarding.

Quality, Documented

Every prototype and pilot is traceable. We keep the paperwork tight so your scale-up stays predictable and audits stay straightforward.

- Ingredient identity & potency verification

- Microbial and heavy metal compliance

- In-process checks and final release tests

- Change control and versioned formulas

Delivery Forms We Develop

Choose the experience that fits your customer and claim strategy—then let our team engineer it to scale.

Solid Dose

- Capsules (gelatin & veggie)

- Tablets (IR/ER, chewable, ODT)

- Beadlets & microencapsulation

- Softgels (by facility)

Powders & Gummies

- Protein & greens blends

- Effervescents & stick packs

- Pectin & gelatin gummies

- Electrolyte & hydration mixes

Liquids & Specialty

- Tinctures & shots

- Probiotic room-temp strategies

- Novel delivery systems

- Channel-specific pack formats

R&D FAQs

Answers to common questions about development speed, scope, and scale-up.

How fast can we move from brief to prototype?

Most projects progress in phased sprints. Timelines depend on ingredient sourcing, dosage form, and evidence required for claims and stability.

Do you help translate R&D data into labels?

Yes. We convert formulation and analytical data into compliant Supplement Facts panels with aligned claims and disclaimers.

What if my flavor target is difficult?

We iterate sweetener/acid systems and flavor maskers, balancing mouthfeel, solubility, and aroma. We aim for consumer-proofed profiles before scale-up.

Can prototypes be piloted before a full PO?

Pilot runs de-risk throughput and yields, confirming excipient and process choices to avoid surprises at production scale.